INSTRUCTIONS FOR BUILDING THE RECEIVER, A component of the multiPIG+

updated 4/6/03 21:17 PM

The RCVR kit includes 6 plastic envelopes and a schematic.

1. RVCR PCB with 2 wires

2. 5 matched crystals and 4 matched varactor diodes

3. Headers, connectors and 6 black toroids and 2 red toroids

4. Resistors, capacitors and mixers.

We will build the RCVR in this order:

0. Review instructions. Inspect PCB and parts.

1. Wind all toroids (hardest part first)

2. Install SMT mixer parts

3. Install all resistors

4. Install all toroids

5. Install capacitors

6. Install the headers

7, Install all discrete components

8. Install the Crystals

9. Test voltage regulator

10. Interconnections to other MP+ components

11. Tune Up and calibration

Ready...set...begin!

INVENTORY all the parts against the parts list.

Be careful not to loose the 2 small short wires in the wire bag.

ERRORS Inspect the PCB. You will find two errors in the layout...

1. A cut in the trace on the back of the PCB behind L9 (lower middle)

We will add a jumper wire after all the other parts are installed.

2. A cut in the trace between R36 and C45 on top in lower left corner.

We will add capacitor C45 after all the other parts are installed.

MODS This modification was added to improve the PLL output waveform.

It your PCB does not have a TRACE CUT on the top of the board from

PIN 2 of J3 to the lower connection of L5, then do so now.

We will solder R21 across the CUT after all the other parts are installed.

WIND TOROIDS (note: there is no L1)

Seperate the 6 black toroids from the connector housing bag. There are three

FT37-43 and three FT37-61. The -61 are dull and gray while the -43 are shiny.

note: All toroids must be wound the same way or they will not fit into the PCB.

The correct winding direction should make the toroids look like this:

____L2 Wind 10 turns of the twisted pair wire onto an FT37-43 toroid evenly spaced.

Cut the 4 ends to about 1/2 inch from the body of the toroid. Note the two colors.

The toroid should look like this with the lead colors alternating.

____L2 Wind 10 turns of the twisted pair wire onto an FT37-43 toroid evenly spaced.

Cut the 4 ends to about 1/2 inch from the body of the toroid. Note the two colors.

The toroid should look like this with the lead colors alternating.

____L3 Wind 18 turns #27 brown wire on a FT37-61 toroid

____L4 Wind 14 and 3 turns #24 brown wire on a red T37-2 toroid; see first picture above

____L5 and L8 Wind 10 turns #27 brown wire on a FT37-43 toroid

____L6 and L7 Wind 17 turns #27 brown wire on two FT37-61 toroids

(note: the wire for L9 is in the PCB bag)

____L9 binocular transformer (L9 instructions from Dennis - WB0WAO)

a. Take #32 wire (red) and insert from either side thru one hole...

b. Loop the wire and pass thru the other hole....

c. Wire will be in the shape of a "U" on its side - this is one turn...

d. Repeat this 5 more time to get 6 turns - both red wires will be sticking

out the same side...

e. Take #30 wire (green)and insert thru one of the holes on the OPPOSITE

side that you started the red wire..

f. Loop the wire and pass thru the other hole....

g. Wire will be in the shape of a "U" on its side - this is one turn...

h. Do this once more to get 2 turns - both green wires will be sticking out

the same side...

i. Install with the end with the red wires coming out towards U4 and the

green wires should be towards X6

____L10 wind 31 turns #28 ga red wire on a red T37-2 toroid

____L3 Wind 18 turns #27 brown wire on a FT37-61 toroid

____L4 Wind 14 and 3 turns #24 brown wire on a red T37-2 toroid; see first picture above

____L5 and L8 Wind 10 turns #27 brown wire on a FT37-43 toroid

____L6 and L7 Wind 17 turns #27 brown wire on two FT37-61 toroids

(note: the wire for L9 is in the PCB bag)

____L9 binocular transformer (L9 instructions from Dennis - WB0WAO)

a. Take #32 wire (red) and insert from either side thru one hole...

b. Loop the wire and pass thru the other hole....

c. Wire will be in the shape of a "U" on its side - this is one turn...

d. Repeat this 5 more time to get 6 turns - both red wires will be sticking

out the same side...

e. Take #30 wire (green)and insert thru one of the holes on the OPPOSITE

side that you started the red wire..

f. Loop the wire and pass thru the other hole....

g. Wire will be in the shape of a "U" on its side - this is one turn...

h. Do this once more to get 2 turns - both green wires will be sticking out

the same side...

i. Install with the end with the red wires coming out towards U4 and the

green wires should be towards X6

____L10 wind 31 turns #28 ga red wire on a red T37-2 toroid

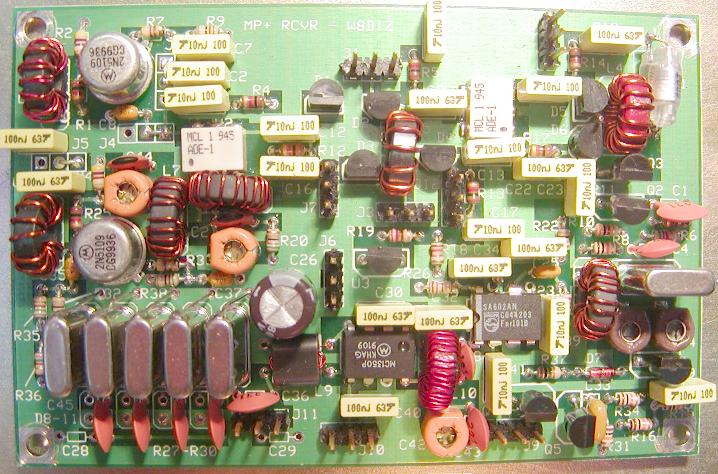

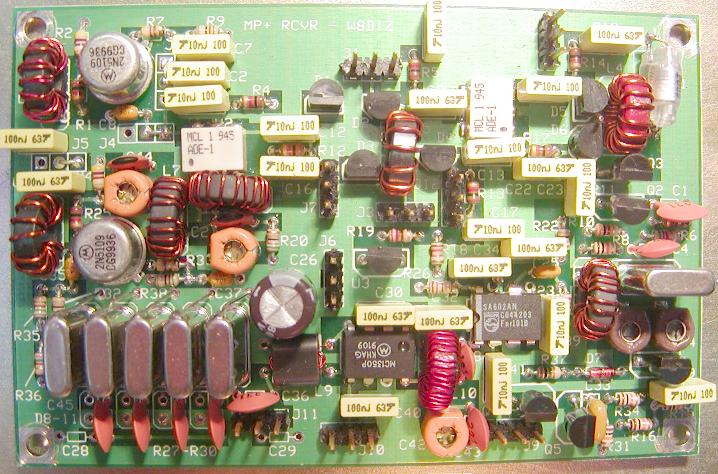

This picture does not show the 3 headers for the PreAmp

It is hard wired to always have the preamp ON.

Also, this version of the RCVR PCB does not use varaactors.

I wanted to test using 330pF fixed caps for the IF XTAL filter.

SMT MIXERS These are the only two surface mount parts.

Remove the mixers from the resistor bag. Carefully scrape the white paint off of the pads

for U1 and U2 on the top of the PCB. Use a small blade screwdriver. You will need fine tip

solder pencil for the SMT mixers. Also, you can position the mixers either way on the PCB.

They are symetrical in pin layout so there is no way to mount them wrong (except for Phil)

____Position U2 on the PCB and align the 6 contacts with the 6 pads. Tack one lead to the

PCB. Solder the other pads to the PCB, then solder the first pad to the PCB.

____Do the same for U1.

Install and solder ALL the resistors.

If you are visually challanged like me, use a magnifying glass to identify the resistors.

Clip the leads close to the board after soldering.

Suggest you install the resistors in this order:

push all resistors flush against the PCB.

NOTE: Save 6 clipped resistor leads for the XTALs.

These will be used to ground the XTAL cans.

____R7 4R7 YELLOW-PURPLE-GOLD top left edge of PCB

____R33 4R7 YELLOW-PURPLE-GOLD to the right of Q6 left center

____R11 27 RED-VIOLET-BLACK between Q2 and Q3 right center

____R22 27 RED-VIOLET-BLACK right center of PCB

____R23 27 RED-VIOLET-BLACK right center below R22

____R9 51 GREEN-BROWN-BLACK top left edge of PCB

____R20 51 GREEN-BROWN-BLACK slightly left of center of PCB

____R38 51 GREEN-BROWN-BLACK just above the Xtal Filter

____R32 75 VIOLET-GREEN-BLACK just left of Xtal Filter

____R19 220 RED-RED-BROWN center of PCB

____R26 120 BROWN-RED-BROWN between U3 and U5 near center

CAUTION: DO NOT MIX UP R10, A 300 ohm WITH A 10K RESISTOR

____R10 300 ORANGE-BLACK-BROWN right center of PCB

____R2 470 YELLOW-VIOLET-BROWN upper left corner

____R24 470 YELLOW-VIOLET-BROWN left above Q6

____R35 750 VIOLET-GREEN-BROWN left of Xtal Filter

____R36 750 VIOLET-GREEN-BROWN left of Xtal Filter

____R1 1K BROWN-BLACK-RED upper left corner

____R3 1K BROWN-BLACK-RED right edge center

____R4 1K BROWN-BLACK-RED above U2 mixer

____R5 1K BROWN-BLACK-RED upper center edge

____R12 1K BROWN-BLACK-RED right of U2 near center

____R13 1K BROWN-BLACK-RED below U1 center

____R14 1K BROWN-BLACK-RED upper right corner

____R17 1K BROWN-BLACK-RED right of U1

____R25 1K BROWN-BLACK-RED left of Q6

____R18 1K2 BROWN-RED-RED right of U3 near center of PCB

____R6 5K6 GREEN=BLUE-RED center right edge of PCB

____R8 10K BROWN-BLACK-ORANGE above X1 right edge

____R15 10K BROWN-BLACK-ORANGE lower right corner

____R16 10K BROWN-BLACK-ORANGE lower right corner

____R31 10K BROWN-BLACK-ORANGE right, bottom edge corner

____R34 10K BROWN-BLACK-ORANGE right, bottom edge corner

____R27 100K BROWN-BLACK-YELLOW below Xtal Filter

____R28 100K BROWN-BLACK-YELLOW below Xtal Filter

____R29 100K BROWN-BLACK-YELLOW below Xtal Filter

____R30 100K BROWN-BLACK-YELLOW below Xtal Filter

____R37 1M BROWN-BLACK-GREEN between U5 and bottom right corner

INSTALL TOROIDS

____L2 Install L2. The outer windings should be different color wire

as should be the inner wires. Upper left corner.

____L3 lower right

____L4 Upper right. The 14 turn winding wires must be soldered in the upper

and lower holes. The middle (inline) holes are for the 3 turn winding.

NOTE: There is an extra hole in the PCB on the trace that connects D6 and L4

This can be used to measure the BFO frequency and to align the XTAL filter

and the XMIT offset. More to follow when we align the RCVR

____L5 Center of board

____L6 Left Center

____L7 Left Center

____L8 Far Left

____L9 Red wires toward U4, the MC1350

____L10 just to the right of U4

INSTALL CAPACITORS

____C21 43pf near Q6

____C44 43pf near Q6

____C14 [Brown or Yellow] 50pF Var Flat edge toward XTAL X1

____C15 [Brown or Yellow] 50pF Var Flat edge toward XTAL X1

____C20 [Orange] 80pF Var Flat edge toward left edge of PCB near Q6

____C24 [Orange] 80pF Var Flat edge toward left edge of PCB near Q6

____C42 [Orange] 80pF Var Flat edge toward L10 bottom edge

____C38 130pF below U5

____C4 220pF above X1

____C43 220pF below U5

____C1 330pF above X1 right edge

____C25 1000pF above U5

____C11 1500pF upper right corner

____C33 47n (22n in schematic) below X1 bottom edge

note:C13 is a bit tight but will fit OK

____C2 10n right of Q1 on top edge

____C5 10n below C2 right of Q1

____C6 10n left of U1 mixer

____C7 10n above C2 right of Q1

____C9 10n right of U1 mixer

____C12 10n upper left center of PCB

____C13 10n upper right center of PCB

____C16 10n below C12 [* SEE SPECIAL NOTE IN HEADER INSTALLATIONS]

____C17 10n below C13

____C19 10n lower right corner

____C23 10n middle right center

____C39 10n right of U5

____C41 10n below U5 bottom edge

The following caps are the Yellow Box shapes

____C3 100n radial near upper edge center of PCB

____C10 100n radial left edge below L2

____C18 100n radial top right corner

____C22 100n radial lower right of U1

____C27 100n radial middle left edge

____C30 100n radial above U4 near center of PCB

____C31 100n radial above U5

____C32 100n radial near Pin 8 of U5

____C34 100n radial above pin 8 of U5

____C40 100n radial below U5 near bottom edge

____C8 100n axial just below Q1

____C28 100n axial below X2 bottom edge

____C29 100n axial below X6 bottom edge

____C35 100n axial left of Q6 near left edge

____C37 100n axial above X6

____C26 220uF above and right of X6 near center of PCB

The next 2 caps can be modified. The are part of the IF BandPass Filter.

____C36 220pF beolow X6

____C45 220pF this cap will be soldered on the bottom of the PCB (later)

INSTALL HEADERS

____J1 3PIN center near top edge

____J2 3PIN right of Q1

____J3 3PIN center of PCB

____J4 3PIN below Q1

____J5 3PIN below Q1 on left edge

____J6 3PIN center of PCB

____J7 3PIN above J6

*NOTE: The right side of C16 should be grounded. PLACE A SOLDER BRIDGE

between the right side of C16 and the top pin of J7 on the bottom of

the RCVR PCB. This will ground the right pin of C16.

These two points are next to each other on the bottom of the PCB.

____J8 3PIN right top edge

____J9 3PIN bottom edge below U5

____J10 3PIN bottom edge center

____J11 3PIN below X6 bottom edge

____J12 3PIN near center below U1

INSTALL DISCRETE COMPONENTS

____D7 1N4148 near lower right corner

Install the PIN diodes about 1/16 inch above the PCB

____D1 D2 MPN3700 upper center of PCB

____D3 D4 MPN3700 below D1 and D2

____D5 D6 MPN3700 near upper right corner

Install the next parts about 3/16 inch above the PCB

____Q2 2N3904 near right edge center

____Q4 2N3904 near right edge lower corner

____Q5 2N3904 bottom edge near right corner

____Q3 2N3906 near right edge center

____Q7 J310 (J201 in schematic) left of Q5 near bottom edge right

____U3 LM317L center of PCB

Install the 2N5109s and/or MRF517 about 1/16 inch above the PCB

____Q1 MRF517 or 2N5109 upper left corner

____Q6 MRF517 or 2N5109 middle left edge

____U4 MC1350 middle near lower edge

*** CAUTION ***

YOU MUST BREAK OFF PINS 5 and 7 on the SA602AM

____U5 SA602AN middle of lower right quadrant

INSTALL CRYSTALS

When soldering the XTALs, tilt the XTALs 10 or 15 degrees

This will keep the metal can from shorting out any traces

below the XTALs.

____X1 4.9152 BFO Xtal right edge middle

____X2 X3 X4 X5 X6 4.9152 Xtal Filter

The next two steps will connect the metal XTAL cans to ground

solder a wire from the hole to the right of X1 to the side of X1

____X1

solder a wire from the holes above the XTALS to the side of XTALs

____X2 X3 X4 X5 X6

Install the VARACTOR diodes about 1/16 inch above the PCB

____D8 D9 D10 D11 MVAM109 lower left corner on bottom edge

This picture does not show the 3 headers for the PreAmp

It is hard wired to always have the preamp ON.

Also, this version of the RCVR PCB does not use varaactors.

I wanted to test using 330pF fixed caps for the IF XTAL filter.

SMT MIXERS These are the only two surface mount parts.

Remove the mixers from the resistor bag. Carefully scrape the white paint off of the pads

for U1 and U2 on the top of the PCB. Use a small blade screwdriver. You will need fine tip

solder pencil for the SMT mixers. Also, you can position the mixers either way on the PCB.

They are symetrical in pin layout so there is no way to mount them wrong (except for Phil)

____Position U2 on the PCB and align the 6 contacts with the 6 pads. Tack one lead to the

PCB. Solder the other pads to the PCB, then solder the first pad to the PCB.

____Do the same for U1.

Install and solder ALL the resistors.

If you are visually challanged like me, use a magnifying glass to identify the resistors.

Clip the leads close to the board after soldering.

Suggest you install the resistors in this order:

push all resistors flush against the PCB.

NOTE: Save 6 clipped resistor leads for the XTALs.

These will be used to ground the XTAL cans.

____R7 4R7 YELLOW-PURPLE-GOLD top left edge of PCB

____R33 4R7 YELLOW-PURPLE-GOLD to the right of Q6 left center

____R11 27 RED-VIOLET-BLACK between Q2 and Q3 right center

____R22 27 RED-VIOLET-BLACK right center of PCB

____R23 27 RED-VIOLET-BLACK right center below R22

____R9 51 GREEN-BROWN-BLACK top left edge of PCB

____R20 51 GREEN-BROWN-BLACK slightly left of center of PCB

____R38 51 GREEN-BROWN-BLACK just above the Xtal Filter

____R32 75 VIOLET-GREEN-BLACK just left of Xtal Filter

____R19 220 RED-RED-BROWN center of PCB

____R26 120 BROWN-RED-BROWN between U3 and U5 near center

CAUTION: DO NOT MIX UP R10, A 300 ohm WITH A 10K RESISTOR

____R10 300 ORANGE-BLACK-BROWN right center of PCB

____R2 470 YELLOW-VIOLET-BROWN upper left corner

____R24 470 YELLOW-VIOLET-BROWN left above Q6

____R35 750 VIOLET-GREEN-BROWN left of Xtal Filter

____R36 750 VIOLET-GREEN-BROWN left of Xtal Filter

____R1 1K BROWN-BLACK-RED upper left corner

____R3 1K BROWN-BLACK-RED right edge center

____R4 1K BROWN-BLACK-RED above U2 mixer

____R5 1K BROWN-BLACK-RED upper center edge

____R12 1K BROWN-BLACK-RED right of U2 near center

____R13 1K BROWN-BLACK-RED below U1 center

____R14 1K BROWN-BLACK-RED upper right corner

____R17 1K BROWN-BLACK-RED right of U1

____R25 1K BROWN-BLACK-RED left of Q6

____R18 1K2 BROWN-RED-RED right of U3 near center of PCB

____R6 5K6 GREEN=BLUE-RED center right edge of PCB

____R8 10K BROWN-BLACK-ORANGE above X1 right edge

____R15 10K BROWN-BLACK-ORANGE lower right corner

____R16 10K BROWN-BLACK-ORANGE lower right corner

____R31 10K BROWN-BLACK-ORANGE right, bottom edge corner

____R34 10K BROWN-BLACK-ORANGE right, bottom edge corner

____R27 100K BROWN-BLACK-YELLOW below Xtal Filter

____R28 100K BROWN-BLACK-YELLOW below Xtal Filter

____R29 100K BROWN-BLACK-YELLOW below Xtal Filter

____R30 100K BROWN-BLACK-YELLOW below Xtal Filter

____R37 1M BROWN-BLACK-GREEN between U5 and bottom right corner

INSTALL TOROIDS

____L2 Install L2. The outer windings should be different color wire

as should be the inner wires. Upper left corner.

____L3 lower right

____L4 Upper right. The 14 turn winding wires must be soldered in the upper

and lower holes. The middle (inline) holes are for the 3 turn winding.

NOTE: There is an extra hole in the PCB on the trace that connects D6 and L4

This can be used to measure the BFO frequency and to align the XTAL filter

and the XMIT offset. More to follow when we align the RCVR

____L5 Center of board

____L6 Left Center

____L7 Left Center

____L8 Far Left

____L9 Red wires toward U4, the MC1350

____L10 just to the right of U4

INSTALL CAPACITORS

____C21 43pf near Q6

____C44 43pf near Q6

____C14 [Brown or Yellow] 50pF Var Flat edge toward XTAL X1

____C15 [Brown or Yellow] 50pF Var Flat edge toward XTAL X1

____C20 [Orange] 80pF Var Flat edge toward left edge of PCB near Q6

____C24 [Orange] 80pF Var Flat edge toward left edge of PCB near Q6

____C42 [Orange] 80pF Var Flat edge toward L10 bottom edge

____C38 130pF below U5

____C4 220pF above X1

____C43 220pF below U5

____C1 330pF above X1 right edge

____C25 1000pF above U5

____C11 1500pF upper right corner

____C33 47n (22n in schematic) below X1 bottom edge

note:C13 is a bit tight but will fit OK

____C2 10n right of Q1 on top edge

____C5 10n below C2 right of Q1

____C6 10n left of U1 mixer

____C7 10n above C2 right of Q1

____C9 10n right of U1 mixer

____C12 10n upper left center of PCB

____C13 10n upper right center of PCB

____C16 10n below C12 [* SEE SPECIAL NOTE IN HEADER INSTALLATIONS]

____C17 10n below C13

____C19 10n lower right corner

____C23 10n middle right center

____C39 10n right of U5

____C41 10n below U5 bottom edge

The following caps are the Yellow Box shapes

____C3 100n radial near upper edge center of PCB

____C10 100n radial left edge below L2

____C18 100n radial top right corner

____C22 100n radial lower right of U1

____C27 100n radial middle left edge

____C30 100n radial above U4 near center of PCB

____C31 100n radial above U5

____C32 100n radial near Pin 8 of U5

____C34 100n radial above pin 8 of U5

____C40 100n radial below U5 near bottom edge

____C8 100n axial just below Q1

____C28 100n axial below X2 bottom edge

____C29 100n axial below X6 bottom edge

____C35 100n axial left of Q6 near left edge

____C37 100n axial above X6

____C26 220uF above and right of X6 near center of PCB

The next 2 caps can be modified. The are part of the IF BandPass Filter.

____C36 220pF beolow X6

____C45 220pF this cap will be soldered on the bottom of the PCB (later)

INSTALL HEADERS

____J1 3PIN center near top edge

____J2 3PIN right of Q1

____J3 3PIN center of PCB

____J4 3PIN below Q1

____J5 3PIN below Q1 on left edge

____J6 3PIN center of PCB

____J7 3PIN above J6

*NOTE: The right side of C16 should be grounded. PLACE A SOLDER BRIDGE

between the right side of C16 and the top pin of J7 on the bottom of

the RCVR PCB. This will ground the right pin of C16.

These two points are next to each other on the bottom of the PCB.

____J8 3PIN right top edge

____J9 3PIN bottom edge below U5

____J10 3PIN bottom edge center

____J11 3PIN below X6 bottom edge

____J12 3PIN near center below U1

INSTALL DISCRETE COMPONENTS

____D7 1N4148 near lower right corner

Install the PIN diodes about 1/16 inch above the PCB

____D1 D2 MPN3700 upper center of PCB

____D3 D4 MPN3700 below D1 and D2

____D5 D6 MPN3700 near upper right corner

Install the next parts about 3/16 inch above the PCB

____Q2 2N3904 near right edge center

____Q4 2N3904 near right edge lower corner

____Q5 2N3904 bottom edge near right corner

____Q3 2N3906 near right edge center

____Q7 J310 (J201 in schematic) left of Q5 near bottom edge right

____U3 LM317L center of PCB

Install the 2N5109s and/or MRF517 about 1/16 inch above the PCB

____Q1 MRF517 or 2N5109 upper left corner

____Q6 MRF517 or 2N5109 middle left edge

____U4 MC1350 middle near lower edge

*** CAUTION ***

YOU MUST BREAK OFF PINS 5 and 7 on the SA602AM

____U5 SA602AN middle of lower right quadrant

INSTALL CRYSTALS

When soldering the XTALs, tilt the XTALs 10 or 15 degrees

This will keep the metal can from shorting out any traces

below the XTALs.

____X1 4.9152 BFO Xtal right edge middle

____X2 X3 X4 X5 X6 4.9152 Xtal Filter

The next two steps will connect the metal XTAL cans to ground

solder a wire from the hole to the right of X1 to the side of X1

____X1

solder a wire from the holes above the XTALS to the side of XTALs

____X2 X3 X4 X5 X6

Install the VARACTOR diodes about 1/16 inch above the PCB

____D8 D9 D10 D11 MVAM109 lower left corner on bottom edge

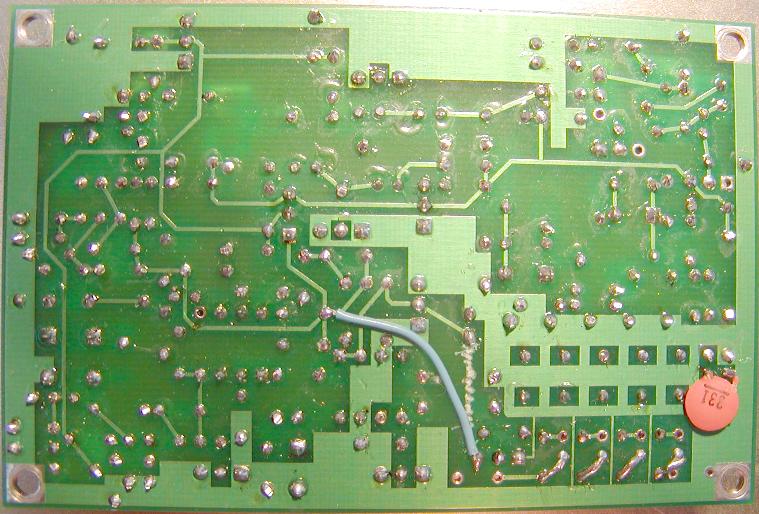

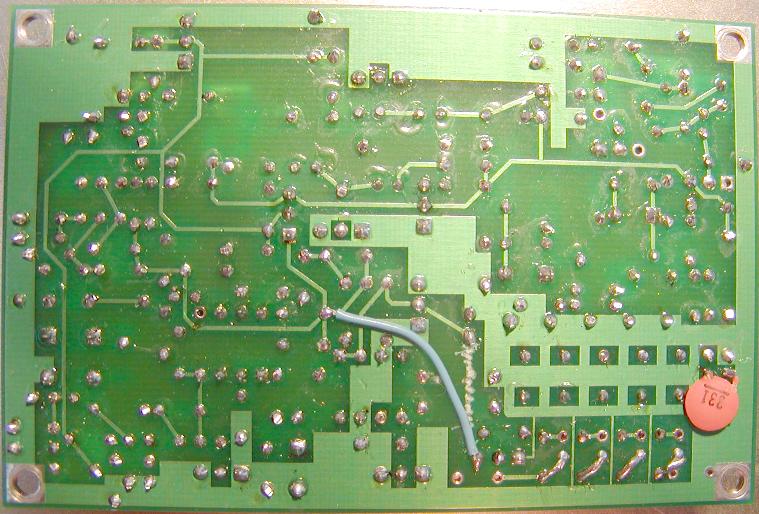

Note the 330pF cap on the bottom of the PCB.

This value should be 220pF (C45) that comes with the kit.

____Install C45 220pF disk cap on the bottom of the PCB per picture

Do not install in the holes marked C45

____Jumper - On the bottom of the PCB, connect a small 1.25 inch

insulated wire from the right pin of J11 (between the pins of C29)

to the left side of C32. This is the point on the bottom of the

PCB that has FOUR circuit paths interconnect.

____R21 51 GREEN-BROWN-BLACK install on the bottom of the RCVR PCB

between Pin 2 of J3 and the junction of PIN diodes D3 and D4.

Note the cut trace on the top of the PCB as a reference.

____Replace 10.24 MHz xtal on the PLL PCB with the included 12.096 MHz.

TEST VOLTAGE REGULATOR LM317L

____Apply 12 volts to the center pin of J6 in the center of the PCB

Measure 8 volts on PIN 1, the lower pin of J12

INTERCONNECT THE RCVR PCB TO OTHER MP+ PCBs

____This requires that ALL PCBs are completed except the XMTR PCB

This step will be detailed in a forthcoming document

TUNE UP, ALIGNMENT AND CALIBRATION

BFO alignment instructions for the RCVR using a Scope.

MP+ Freq Counter (does not need to be calibrated)

1. Solder a 5" insulated wire to the test point on the

top side of the RCVR board. The test point is the vacant

hole between D5 and D6.

2. Connect all wires between the RCVR and the FCC.

3. Run the 5" wire through the center of L6 and connect the

free end to the Freq Counter.

4. Disable the Freq Counter Offset jumper J51

5. Connect the Oscilloscope to PIN 8 of U4 on the RCVR board.

6. Power up the RCVR/FCC

7. Set to Varactor voltage (J11 center pin) to 1.00 Volts.

8. Place the MP+ into XMIT mode; place jumper on J2 on the FCC

9. Adjust C14 AND C15 for a MAXIMUM PEAK signal. This should

be near 4,913,700 Hz. This is the XMIT BFO freq.

At this point, you need to decide on your favorite audio CW note.

Most CW operators like to listen to 600 to 700 Hz signals.

Calculate the RCVE BFO freq by adding your desired audio freq

to the XMTR BFO freq. In this example, my favorite audio freq

is near 700 Hz so the calculated RCVR BFO freq = 4,914,400

10. Place the MP+ into RCVE mode; remove J2 jumper

11. Adjust C14 on the RCVR to 4,914,400 or YOUR freq.

12. Place the MP+ into XMIT mode; replace J2 jumper

13. Adjust C15 on the RCVR to 4,913,700 or YOUR freq.

14. Repeat steps 10 thru 13 until there is no more

interaction between C14 and C15 adjustments.

BFO alignment instructions for the RCVR without using a Scope.

MP+ Freq Counter (does not need to be calibrated)

The BPF must be aligned before calibrating the BFO.

1. Interconnect all six MP+ PC boards along

with all controls and the speaker.

2. Connect the Freq Counter to the test point in the vacant

hole between D5 and D6. If you have not soldered a small

wire to the test point, do so now; about 1/2" will do.

3. Disable the Freq Counter Offset jumper J51

4. Connect an antenna to the BPF on the 40 meter port

Enable the RCVR PreAmp with jumpers J2, J4 and J5.

5. Power up the MP+

6. Set the PLL to 7040 on 40 meters

7. Set to Varactor voltage (J11 center pin) to 1.00 Volts.

8. Also adjust C14, C15, C20, C24 and C42 for maximum speaker noise.

9. Listen to a signal source from the antenna; either a CW QSO or

a locally generated signal. Tune across the signal and lock it

to a comfortable audio peak frequency near 700 Hz.

You will have to adjust C14 and C15 again to accomplish this.

Make sure that when you tune across the CW note that the signal

drops out of the Xtal Filter bandpass at high audio freqs and

also that the signal is NOT audible on the other sideband.

When you find a good adjustment for C14 and C15, check the

Freq Counter. It should read near 4,914,400 Hz +/- 100 Hz

This is the RCVE BFO freq.

Calculate the XMIT BFO freq by subtracting your desired audio freq

to the RCVR BFO freq. In this example, my favorite audio freq

is near 700 Hz so the calculated XMTR BFO freq = 4,913,700

10. Place the MP+ into XMIT mode; place jumper on J2

11. Adjust C15 on the RCVR to 4,913,700 or YOUR freq.

12. Place the MP+ into RCVE mode; remove J2 jumper

13. Adjust C14 on the RCVR to 4,914,400 or YOUR freq.

14. Repeat steps 10 thru 13 until there is no more

interaction between C14 and C15 adjustments.

NEED HELP?

Email me ... w8diz at fpqrp.com

Note the 330pF cap on the bottom of the PCB.

This value should be 220pF (C45) that comes with the kit.

____Install C45 220pF disk cap on the bottom of the PCB per picture

Do not install in the holes marked C45

____Jumper - On the bottom of the PCB, connect a small 1.25 inch

insulated wire from the right pin of J11 (between the pins of C29)

to the left side of C32. This is the point on the bottom of the

PCB that has FOUR circuit paths interconnect.

____R21 51 GREEN-BROWN-BLACK install on the bottom of the RCVR PCB

between Pin 2 of J3 and the junction of PIN diodes D3 and D4.

Note the cut trace on the top of the PCB as a reference.

____Replace 10.24 MHz xtal on the PLL PCB with the included 12.096 MHz.

TEST VOLTAGE REGULATOR LM317L

____Apply 12 volts to the center pin of J6 in the center of the PCB

Measure 8 volts on PIN 1, the lower pin of J12

INTERCONNECT THE RCVR PCB TO OTHER MP+ PCBs

____This requires that ALL PCBs are completed except the XMTR PCB

This step will be detailed in a forthcoming document

TUNE UP, ALIGNMENT AND CALIBRATION

BFO alignment instructions for the RCVR using a Scope.

MP+ Freq Counter (does not need to be calibrated)

1. Solder a 5" insulated wire to the test point on the

top side of the RCVR board. The test point is the vacant

hole between D5 and D6.

2. Connect all wires between the RCVR and the FCC.

3. Run the 5" wire through the center of L6 and connect the

free end to the Freq Counter.

4. Disable the Freq Counter Offset jumper J51

5. Connect the Oscilloscope to PIN 8 of U4 on the RCVR board.

6. Power up the RCVR/FCC

7. Set to Varactor voltage (J11 center pin) to 1.00 Volts.

8. Place the MP+ into XMIT mode; place jumper on J2 on the FCC

9. Adjust C14 AND C15 for a MAXIMUM PEAK signal. This should

be near 4,913,700 Hz. This is the XMIT BFO freq.

At this point, you need to decide on your favorite audio CW note.

Most CW operators like to listen to 600 to 700 Hz signals.

Calculate the RCVE BFO freq by adding your desired audio freq

to the XMTR BFO freq. In this example, my favorite audio freq

is near 700 Hz so the calculated RCVR BFO freq = 4,914,400

10. Place the MP+ into RCVE mode; remove J2 jumper

11. Adjust C14 on the RCVR to 4,914,400 or YOUR freq.

12. Place the MP+ into XMIT mode; replace J2 jumper

13. Adjust C15 on the RCVR to 4,913,700 or YOUR freq.

14. Repeat steps 10 thru 13 until there is no more

interaction between C14 and C15 adjustments.

BFO alignment instructions for the RCVR without using a Scope.

MP+ Freq Counter (does not need to be calibrated)

The BPF must be aligned before calibrating the BFO.

1. Interconnect all six MP+ PC boards along

with all controls and the speaker.

2. Connect the Freq Counter to the test point in the vacant

hole between D5 and D6. If you have not soldered a small

wire to the test point, do so now; about 1/2" will do.

3. Disable the Freq Counter Offset jumper J51

4. Connect an antenna to the BPF on the 40 meter port

Enable the RCVR PreAmp with jumpers J2, J4 and J5.

5. Power up the MP+

6. Set the PLL to 7040 on 40 meters

7. Set to Varactor voltage (J11 center pin) to 1.00 Volts.

8. Also adjust C14, C15, C20, C24 and C42 for maximum speaker noise.

9. Listen to a signal source from the antenna; either a CW QSO or

a locally generated signal. Tune across the signal and lock it

to a comfortable audio peak frequency near 700 Hz.

You will have to adjust C14 and C15 again to accomplish this.

Make sure that when you tune across the CW note that the signal

drops out of the Xtal Filter bandpass at high audio freqs and

also that the signal is NOT audible on the other sideband.

When you find a good adjustment for C14 and C15, check the

Freq Counter. It should read near 4,914,400 Hz +/- 100 Hz

This is the RCVE BFO freq.

Calculate the XMIT BFO freq by subtracting your desired audio freq

to the RCVR BFO freq. In this example, my favorite audio freq

is near 700 Hz so the calculated XMTR BFO freq = 4,913,700

10. Place the MP+ into XMIT mode; place jumper on J2

11. Adjust C15 on the RCVR to 4,913,700 or YOUR freq.

12. Place the MP+ into RCVE mode; remove J2 jumper

13. Adjust C14 on the RCVR to 4,914,400 or YOUR freq.

14. Repeat steps 10 thru 13 until there is no more

interaction between C14 and C15 adjustments.

NEED HELP?

Email me ... w8diz at fpqrp.com

____L2 Wind 10 turns of the twisted pair wire onto an FT37-43 toroid evenly spaced.

Cut the 4 ends to about 1/2 inch from the body of the toroid. Note the two colors.

The toroid should look like this with the lead colors alternating.

____L2 Wind 10 turns of the twisted pair wire onto an FT37-43 toroid evenly spaced.

Cut the 4 ends to about 1/2 inch from the body of the toroid. Note the two colors.

The toroid should look like this with the lead colors alternating.

____L3 Wind 18 turns #27 brown wire on a FT37-61 toroid

____L4 Wind 14 and 3 turns #24 brown wire on a red T37-2 toroid; see first picture above

____L5 and L8 Wind 10 turns #27 brown wire on a FT37-43 toroid

____L6 and L7 Wind 17 turns #27 brown wire on two FT37-61 toroids

(note: the wire for L9 is in the PCB bag)

____L9 binocular transformer (L9 instructions from Dennis - WB0WAO)

a. Take #32 wire (red) and insert from either side thru one hole...

b. Loop the wire and pass thru the other hole....

c. Wire will be in the shape of a "U" on its side - this is one turn...

d. Repeat this 5 more time to get 6 turns - both red wires will be sticking

out the same side...

e. Take #30 wire (green)and insert thru one of the holes on the OPPOSITE

side that you started the red wire..

f. Loop the wire and pass thru the other hole....

g. Wire will be in the shape of a "U" on its side - this is one turn...

h. Do this once more to get 2 turns - both green wires will be sticking out

the same side...

i. Install with the end with the red wires coming out towards U4 and the

green wires should be towards X6

____L10 wind 31 turns #28 ga red wire on a red T37-2 toroid

____L3 Wind 18 turns #27 brown wire on a FT37-61 toroid

____L4 Wind 14 and 3 turns #24 brown wire on a red T37-2 toroid; see first picture above

____L5 and L8 Wind 10 turns #27 brown wire on a FT37-43 toroid

____L6 and L7 Wind 17 turns #27 brown wire on two FT37-61 toroids

(note: the wire for L9 is in the PCB bag)

____L9 binocular transformer (L9 instructions from Dennis - WB0WAO)

a. Take #32 wire (red) and insert from either side thru one hole...

b. Loop the wire and pass thru the other hole....

c. Wire will be in the shape of a "U" on its side - this is one turn...

d. Repeat this 5 more time to get 6 turns - both red wires will be sticking

out the same side...

e. Take #30 wire (green)and insert thru one of the holes on the OPPOSITE

side that you started the red wire..

f. Loop the wire and pass thru the other hole....

g. Wire will be in the shape of a "U" on its side - this is one turn...

h. Do this once more to get 2 turns - both green wires will be sticking out

the same side...

i. Install with the end with the red wires coming out towards U4 and the

green wires should be towards X6

____L10 wind 31 turns #28 ga red wire on a red T37-2 toroid

This picture does not show the 3 headers for the PreAmp

It is hard wired to always have the preamp ON.

Also, this version of the RCVR PCB does not use varaactors.

I wanted to test using 330pF fixed caps for the IF XTAL filter.

SMT MIXERS These are the only two surface mount parts.

Remove the mixers from the resistor bag. Carefully scrape the white paint off of the pads

for U1 and U2 on the top of the PCB. Use a small blade screwdriver. You will need fine tip

solder pencil for the SMT mixers. Also, you can position the mixers either way on the PCB.

They are symetrical in pin layout so there is no way to mount them wrong (except for Phil)

____Position U2 on the PCB and align the 6 contacts with the 6 pads. Tack one lead to the

PCB. Solder the other pads to the PCB, then solder the first pad to the PCB.

____Do the same for U1.

Install and solder ALL the resistors.

If you are visually challanged like me, use a magnifying glass to identify the resistors.

Clip the leads close to the board after soldering.

Suggest you install the resistors in this order:

push all resistors flush against the PCB.

NOTE: Save 6 clipped resistor leads for the XTALs.

These will be used to ground the XTAL cans.

____R7 4R7 YELLOW-PURPLE-GOLD top left edge of PCB

____R33 4R7 YELLOW-PURPLE-GOLD to the right of Q6 left center

____R11 27 RED-VIOLET-BLACK between Q2 and Q3 right center

____R22 27 RED-VIOLET-BLACK right center of PCB

____R23 27 RED-VIOLET-BLACK right center below R22

____R9 51 GREEN-BROWN-BLACK top left edge of PCB

____R20 51 GREEN-BROWN-BLACK slightly left of center of PCB

____R38 51 GREEN-BROWN-BLACK just above the Xtal Filter

____R32 75 VIOLET-GREEN-BLACK just left of Xtal Filter

____R19 220 RED-RED-BROWN center of PCB

____R26 120 BROWN-RED-BROWN between U3 and U5 near center

CAUTION: DO NOT MIX UP R10, A 300 ohm WITH A 10K RESISTOR

____R10 300 ORANGE-BLACK-BROWN right center of PCB

____R2 470 YELLOW-VIOLET-BROWN upper left corner

____R24 470 YELLOW-VIOLET-BROWN left above Q6

____R35 750 VIOLET-GREEN-BROWN left of Xtal Filter

____R36 750 VIOLET-GREEN-BROWN left of Xtal Filter

____R1 1K BROWN-BLACK-RED upper left corner

____R3 1K BROWN-BLACK-RED right edge center

____R4 1K BROWN-BLACK-RED above U2 mixer

____R5 1K BROWN-BLACK-RED upper center edge

____R12 1K BROWN-BLACK-RED right of U2 near center

____R13 1K BROWN-BLACK-RED below U1 center

____R14 1K BROWN-BLACK-RED upper right corner

____R17 1K BROWN-BLACK-RED right of U1

____R25 1K BROWN-BLACK-RED left of Q6

____R18 1K2 BROWN-RED-RED right of U3 near center of PCB

____R6 5K6 GREEN=BLUE-RED center right edge of PCB

____R8 10K BROWN-BLACK-ORANGE above X1 right edge

____R15 10K BROWN-BLACK-ORANGE lower right corner

____R16 10K BROWN-BLACK-ORANGE lower right corner

____R31 10K BROWN-BLACK-ORANGE right, bottom edge corner

____R34 10K BROWN-BLACK-ORANGE right, bottom edge corner

____R27 100K BROWN-BLACK-YELLOW below Xtal Filter

____R28 100K BROWN-BLACK-YELLOW below Xtal Filter

____R29 100K BROWN-BLACK-YELLOW below Xtal Filter

____R30 100K BROWN-BLACK-YELLOW below Xtal Filter

____R37 1M BROWN-BLACK-GREEN between U5 and bottom right corner

INSTALL TOROIDS

____L2 Install L2. The outer windings should be different color wire

as should be the inner wires. Upper left corner.

____L3 lower right

____L4 Upper right. The 14 turn winding wires must be soldered in the upper

and lower holes. The middle (inline) holes are for the 3 turn winding.

NOTE: There is an extra hole in the PCB on the trace that connects D6 and L4

This can be used to measure the BFO frequency and to align the XTAL filter

and the XMIT offset. More to follow when we align the RCVR

____L5 Center of board

____L6 Left Center

____L7 Left Center

____L8 Far Left

____L9 Red wires toward U4, the MC1350

____L10 just to the right of U4

INSTALL CAPACITORS

____C21 43pf near Q6

____C44 43pf near Q6

____C14 [Brown or Yellow] 50pF Var Flat edge toward XTAL X1

____C15 [Brown or Yellow] 50pF Var Flat edge toward XTAL X1

____C20 [Orange] 80pF Var Flat edge toward left edge of PCB near Q6

____C24 [Orange] 80pF Var Flat edge toward left edge of PCB near Q6

____C42 [Orange] 80pF Var Flat edge toward L10 bottom edge

____C38 130pF below U5

____C4 220pF above X1

____C43 220pF below U5

____C1 330pF above X1 right edge

____C25 1000pF above U5

____C11 1500pF upper right corner

____C33 47n (22n in schematic) below X1 bottom edge

note:C13 is a bit tight but will fit OK

____C2 10n right of Q1 on top edge

____C5 10n below C2 right of Q1

____C6 10n left of U1 mixer

____C7 10n above C2 right of Q1

____C9 10n right of U1 mixer

____C12 10n upper left center of PCB

____C13 10n upper right center of PCB

____C16 10n below C12 [* SEE SPECIAL NOTE IN HEADER INSTALLATIONS]

____C17 10n below C13

____C19 10n lower right corner

____C23 10n middle right center

____C39 10n right of U5

____C41 10n below U5 bottom edge

The following caps are the Yellow Box shapes

____C3 100n radial near upper edge center of PCB

____C10 100n radial left edge below L2

____C18 100n radial top right corner

____C22 100n radial lower right of U1

____C27 100n radial middle left edge

____C30 100n radial above U4 near center of PCB

____C31 100n radial above U5

____C32 100n radial near Pin 8 of U5

____C34 100n radial above pin 8 of U5

____C40 100n radial below U5 near bottom edge

____C8 100n axial just below Q1

____C28 100n axial below X2 bottom edge

____C29 100n axial below X6 bottom edge

____C35 100n axial left of Q6 near left edge

____C37 100n axial above X6

____C26 220uF above and right of X6 near center of PCB

The next 2 caps can be modified. The are part of the IF BandPass Filter.

____C36 220pF beolow X6

____C45 220pF this cap will be soldered on the bottom of the PCB (later)

INSTALL HEADERS

____J1 3PIN center near top edge

____J2 3PIN right of Q1

____J3 3PIN center of PCB

____J4 3PIN below Q1

____J5 3PIN below Q1 on left edge

____J6 3PIN center of PCB

____J7 3PIN above J6

*NOTE: The right side of C16 should be grounded. PLACE A SOLDER BRIDGE

between the right side of C16 and the top pin of J7 on the bottom of

the RCVR PCB. This will ground the right pin of C16.

These two points are next to each other on the bottom of the PCB.

____J8 3PIN right top edge

____J9 3PIN bottom edge below U5

____J10 3PIN bottom edge center

____J11 3PIN below X6 bottom edge

____J12 3PIN near center below U1

INSTALL DISCRETE COMPONENTS

____D7 1N4148 near lower right corner

Install the PIN diodes about 1/16 inch above the PCB

____D1 D2 MPN3700 upper center of PCB

____D3 D4 MPN3700 below D1 and D2

____D5 D6 MPN3700 near upper right corner

Install the next parts about 3/16 inch above the PCB

____Q2 2N3904 near right edge center

____Q4 2N3904 near right edge lower corner

____Q5 2N3904 bottom edge near right corner

____Q3 2N3906 near right edge center

____Q7 J310 (J201 in schematic) left of Q5 near bottom edge right

____U3 LM317L center of PCB

Install the 2N5109s and/or MRF517 about 1/16 inch above the PCB

____Q1 MRF517 or 2N5109 upper left corner

____Q6 MRF517 or 2N5109 middle left edge

____U4 MC1350 middle near lower edge

*** CAUTION ***

YOU MUST BREAK OFF PINS 5 and 7 on the SA602AM

____U5 SA602AN middle of lower right quadrant

INSTALL CRYSTALS

When soldering the XTALs, tilt the XTALs 10 or 15 degrees

This will keep the metal can from shorting out any traces

below the XTALs.

____X1 4.9152 BFO Xtal right edge middle

____X2 X3 X4 X5 X6 4.9152 Xtal Filter

The next two steps will connect the metal XTAL cans to ground

solder a wire from the hole to the right of X1 to the side of X1

____X1

solder a wire from the holes above the XTALS to the side of XTALs

____X2 X3 X4 X5 X6

Install the VARACTOR diodes about 1/16 inch above the PCB

____D8 D9 D10 D11 MVAM109 lower left corner on bottom edge

This picture does not show the 3 headers for the PreAmp

It is hard wired to always have the preamp ON.

Also, this version of the RCVR PCB does not use varaactors.

I wanted to test using 330pF fixed caps for the IF XTAL filter.

SMT MIXERS These are the only two surface mount parts.

Remove the mixers from the resistor bag. Carefully scrape the white paint off of the pads

for U1 and U2 on the top of the PCB. Use a small blade screwdriver. You will need fine tip

solder pencil for the SMT mixers. Also, you can position the mixers either way on the PCB.

They are symetrical in pin layout so there is no way to mount them wrong (except for Phil)

____Position U2 on the PCB and align the 6 contacts with the 6 pads. Tack one lead to the

PCB. Solder the other pads to the PCB, then solder the first pad to the PCB.

____Do the same for U1.

Install and solder ALL the resistors.

If you are visually challanged like me, use a magnifying glass to identify the resistors.

Clip the leads close to the board after soldering.

Suggest you install the resistors in this order:

push all resistors flush against the PCB.

NOTE: Save 6 clipped resistor leads for the XTALs.

These will be used to ground the XTAL cans.

____R7 4R7 YELLOW-PURPLE-GOLD top left edge of PCB

____R33 4R7 YELLOW-PURPLE-GOLD to the right of Q6 left center

____R11 27 RED-VIOLET-BLACK between Q2 and Q3 right center

____R22 27 RED-VIOLET-BLACK right center of PCB

____R23 27 RED-VIOLET-BLACK right center below R22

____R9 51 GREEN-BROWN-BLACK top left edge of PCB

____R20 51 GREEN-BROWN-BLACK slightly left of center of PCB

____R38 51 GREEN-BROWN-BLACK just above the Xtal Filter

____R32 75 VIOLET-GREEN-BLACK just left of Xtal Filter

____R19 220 RED-RED-BROWN center of PCB

____R26 120 BROWN-RED-BROWN between U3 and U5 near center

CAUTION: DO NOT MIX UP R10, A 300 ohm WITH A 10K RESISTOR

____R10 300 ORANGE-BLACK-BROWN right center of PCB

____R2 470 YELLOW-VIOLET-BROWN upper left corner

____R24 470 YELLOW-VIOLET-BROWN left above Q6

____R35 750 VIOLET-GREEN-BROWN left of Xtal Filter

____R36 750 VIOLET-GREEN-BROWN left of Xtal Filter

____R1 1K BROWN-BLACK-RED upper left corner

____R3 1K BROWN-BLACK-RED right edge center

____R4 1K BROWN-BLACK-RED above U2 mixer

____R5 1K BROWN-BLACK-RED upper center edge

____R12 1K BROWN-BLACK-RED right of U2 near center

____R13 1K BROWN-BLACK-RED below U1 center

____R14 1K BROWN-BLACK-RED upper right corner

____R17 1K BROWN-BLACK-RED right of U1

____R25 1K BROWN-BLACK-RED left of Q6

____R18 1K2 BROWN-RED-RED right of U3 near center of PCB

____R6 5K6 GREEN=BLUE-RED center right edge of PCB

____R8 10K BROWN-BLACK-ORANGE above X1 right edge

____R15 10K BROWN-BLACK-ORANGE lower right corner

____R16 10K BROWN-BLACK-ORANGE lower right corner

____R31 10K BROWN-BLACK-ORANGE right, bottom edge corner

____R34 10K BROWN-BLACK-ORANGE right, bottom edge corner

____R27 100K BROWN-BLACK-YELLOW below Xtal Filter

____R28 100K BROWN-BLACK-YELLOW below Xtal Filter

____R29 100K BROWN-BLACK-YELLOW below Xtal Filter

____R30 100K BROWN-BLACK-YELLOW below Xtal Filter

____R37 1M BROWN-BLACK-GREEN between U5 and bottom right corner

INSTALL TOROIDS

____L2 Install L2. The outer windings should be different color wire

as should be the inner wires. Upper left corner.

____L3 lower right

____L4 Upper right. The 14 turn winding wires must be soldered in the upper

and lower holes. The middle (inline) holes are for the 3 turn winding.

NOTE: There is an extra hole in the PCB on the trace that connects D6 and L4

This can be used to measure the BFO frequency and to align the XTAL filter

and the XMIT offset. More to follow when we align the RCVR

____L5 Center of board

____L6 Left Center

____L7 Left Center

____L8 Far Left

____L9 Red wires toward U4, the MC1350

____L10 just to the right of U4

INSTALL CAPACITORS

____C21 43pf near Q6

____C44 43pf near Q6

____C14 [Brown or Yellow] 50pF Var Flat edge toward XTAL X1

____C15 [Brown or Yellow] 50pF Var Flat edge toward XTAL X1

____C20 [Orange] 80pF Var Flat edge toward left edge of PCB near Q6

____C24 [Orange] 80pF Var Flat edge toward left edge of PCB near Q6

____C42 [Orange] 80pF Var Flat edge toward L10 bottom edge

____C38 130pF below U5

____C4 220pF above X1

____C43 220pF below U5

____C1 330pF above X1 right edge

____C25 1000pF above U5

____C11 1500pF upper right corner

____C33 47n (22n in schematic) below X1 bottom edge

note:C13 is a bit tight but will fit OK

____C2 10n right of Q1 on top edge

____C5 10n below C2 right of Q1

____C6 10n left of U1 mixer

____C7 10n above C2 right of Q1

____C9 10n right of U1 mixer

____C12 10n upper left center of PCB

____C13 10n upper right center of PCB

____C16 10n below C12 [* SEE SPECIAL NOTE IN HEADER INSTALLATIONS]

____C17 10n below C13

____C19 10n lower right corner

____C23 10n middle right center

____C39 10n right of U5

____C41 10n below U5 bottom edge

The following caps are the Yellow Box shapes

____C3 100n radial near upper edge center of PCB

____C10 100n radial left edge below L2

____C18 100n radial top right corner

____C22 100n radial lower right of U1

____C27 100n radial middle left edge

____C30 100n radial above U4 near center of PCB

____C31 100n radial above U5

____C32 100n radial near Pin 8 of U5

____C34 100n radial above pin 8 of U5

____C40 100n radial below U5 near bottom edge

____C8 100n axial just below Q1

____C28 100n axial below X2 bottom edge

____C29 100n axial below X6 bottom edge

____C35 100n axial left of Q6 near left edge

____C37 100n axial above X6

____C26 220uF above and right of X6 near center of PCB

The next 2 caps can be modified. The are part of the IF BandPass Filter.

____C36 220pF beolow X6

____C45 220pF this cap will be soldered on the bottom of the PCB (later)

INSTALL HEADERS

____J1 3PIN center near top edge

____J2 3PIN right of Q1

____J3 3PIN center of PCB

____J4 3PIN below Q1

____J5 3PIN below Q1 on left edge

____J6 3PIN center of PCB

____J7 3PIN above J6

*NOTE: The right side of C16 should be grounded. PLACE A SOLDER BRIDGE

between the right side of C16 and the top pin of J7 on the bottom of

the RCVR PCB. This will ground the right pin of C16.

These two points are next to each other on the bottom of the PCB.

____J8 3PIN right top edge

____J9 3PIN bottom edge below U5

____J10 3PIN bottom edge center

____J11 3PIN below X6 bottom edge

____J12 3PIN near center below U1

INSTALL DISCRETE COMPONENTS

____D7 1N4148 near lower right corner

Install the PIN diodes about 1/16 inch above the PCB

____D1 D2 MPN3700 upper center of PCB

____D3 D4 MPN3700 below D1 and D2

____D5 D6 MPN3700 near upper right corner

Install the next parts about 3/16 inch above the PCB

____Q2 2N3904 near right edge center

____Q4 2N3904 near right edge lower corner

____Q5 2N3904 bottom edge near right corner

____Q3 2N3906 near right edge center

____Q7 J310 (J201 in schematic) left of Q5 near bottom edge right

____U3 LM317L center of PCB

Install the 2N5109s and/or MRF517 about 1/16 inch above the PCB

____Q1 MRF517 or 2N5109 upper left corner

____Q6 MRF517 or 2N5109 middle left edge

____U4 MC1350 middle near lower edge

*** CAUTION ***

YOU MUST BREAK OFF PINS 5 and 7 on the SA602AM

____U5 SA602AN middle of lower right quadrant

INSTALL CRYSTALS

When soldering the XTALs, tilt the XTALs 10 or 15 degrees

This will keep the metal can from shorting out any traces

below the XTALs.

____X1 4.9152 BFO Xtal right edge middle

____X2 X3 X4 X5 X6 4.9152 Xtal Filter

The next two steps will connect the metal XTAL cans to ground

solder a wire from the hole to the right of X1 to the side of X1

____X1

solder a wire from the holes above the XTALS to the side of XTALs

____X2 X3 X4 X5 X6

Install the VARACTOR diodes about 1/16 inch above the PCB

____D8 D9 D10 D11 MVAM109 lower left corner on bottom edge

Note the 330pF cap on the bottom of the PCB.

This value should be 220pF (C45) that comes with the kit.

____Install C45 220pF disk cap on the bottom of the PCB per picture

Do not install in the holes marked C45

____Jumper - On the bottom of the PCB, connect a small 1.25 inch

insulated wire from the right pin of J11 (between the pins of C29)

to the left side of C32. This is the point on the bottom of the

PCB that has FOUR circuit paths interconnect.

____R21 51 GREEN-BROWN-BLACK install on the bottom of the RCVR PCB

between Pin 2 of J3 and the junction of PIN diodes D3 and D4.

Note the cut trace on the top of the PCB as a reference.

____Replace 10.24 MHz xtal on the PLL PCB with the included 12.096 MHz.

TEST VOLTAGE REGULATOR LM317L

____Apply 12 volts to the center pin of J6 in the center of the PCB

Measure 8 volts on PIN 1, the lower pin of J12

INTERCONNECT THE RCVR PCB TO OTHER MP+ PCBs

____This requires that ALL PCBs are completed except the XMTR PCB

This step will be detailed in a forthcoming document

TUNE UP, ALIGNMENT AND CALIBRATION

BFO alignment instructions for the RCVR using a Scope.

MP+ Freq Counter (does not need to be calibrated)

1. Solder a 5" insulated wire to the test point on the

top side of the RCVR board. The test point is the vacant

hole between D5 and D6.

2. Connect all wires between the RCVR and the FCC.

3. Run the 5" wire through the center of L6 and connect the

free end to the Freq Counter.

4. Disable the Freq Counter Offset jumper J51

5. Connect the Oscilloscope to PIN 8 of U4 on the RCVR board.

6. Power up the RCVR/FCC

7. Set to Varactor voltage (J11 center pin) to 1.00 Volts.

8. Place the MP+ into XMIT mode; place jumper on J2 on the FCC

9. Adjust C14 AND C15 for a MAXIMUM PEAK signal. This should

be near 4,913,700 Hz. This is the XMIT BFO freq.

At this point, you need to decide on your favorite audio CW note.

Most CW operators like to listen to 600 to 700 Hz signals.

Calculate the RCVE BFO freq by adding your desired audio freq

to the XMTR BFO freq. In this example, my favorite audio freq

is near 700 Hz so the calculated RCVR BFO freq = 4,914,400

10. Place the MP+ into RCVE mode; remove J2 jumper

11. Adjust C14 on the RCVR to 4,914,400 or YOUR freq.

12. Place the MP+ into XMIT mode; replace J2 jumper

13. Adjust C15 on the RCVR to 4,913,700 or YOUR freq.

14. Repeat steps 10 thru 13 until there is no more

interaction between C14 and C15 adjustments.

BFO alignment instructions for the RCVR without using a Scope.

MP+ Freq Counter (does not need to be calibrated)

The BPF must be aligned before calibrating the BFO.

1. Interconnect all six MP+ PC boards along

with all controls and the speaker.

2. Connect the Freq Counter to the test point in the vacant

hole between D5 and D6. If you have not soldered a small

wire to the test point, do so now; about 1/2" will do.

3. Disable the Freq Counter Offset jumper J51

4. Connect an antenna to the BPF on the 40 meter port

Enable the RCVR PreAmp with jumpers J2, J4 and J5.

5. Power up the MP+

6. Set the PLL to 7040 on 40 meters

7. Set to Varactor voltage (J11 center pin) to 1.00 Volts.

8. Also adjust C14, C15, C20, C24 and C42 for maximum speaker noise.

9. Listen to a signal source from the antenna; either a CW QSO or

a locally generated signal. Tune across the signal and lock it

to a comfortable audio peak frequency near 700 Hz.

You will have to adjust C14 and C15 again to accomplish this.

Make sure that when you tune across the CW note that the signal

drops out of the Xtal Filter bandpass at high audio freqs and

also that the signal is NOT audible on the other sideband.

When you find a good adjustment for C14 and C15, check the

Freq Counter. It should read near 4,914,400 Hz +/- 100 Hz

This is the RCVE BFO freq.

Calculate the XMIT BFO freq by subtracting your desired audio freq

to the RCVR BFO freq. In this example, my favorite audio freq

is near 700 Hz so the calculated XMTR BFO freq = 4,913,700

10. Place the MP+ into XMIT mode; place jumper on J2

11. Adjust C15 on the RCVR to 4,913,700 or YOUR freq.

12. Place the MP+ into RCVE mode; remove J2 jumper

13. Adjust C14 on the RCVR to 4,914,400 or YOUR freq.

14. Repeat steps 10 thru 13 until there is no more

interaction between C14 and C15 adjustments.

NEED HELP?

Email me ... w8diz at fpqrp.com

Note the 330pF cap on the bottom of the PCB.

This value should be 220pF (C45) that comes with the kit.

____Install C45 220pF disk cap on the bottom of the PCB per picture

Do not install in the holes marked C45

____Jumper - On the bottom of the PCB, connect a small 1.25 inch

insulated wire from the right pin of J11 (between the pins of C29)

to the left side of C32. This is the point on the bottom of the

PCB that has FOUR circuit paths interconnect.

____R21 51 GREEN-BROWN-BLACK install on the bottom of the RCVR PCB

between Pin 2 of J3 and the junction of PIN diodes D3 and D4.

Note the cut trace on the top of the PCB as a reference.

____Replace 10.24 MHz xtal on the PLL PCB with the included 12.096 MHz.

TEST VOLTAGE REGULATOR LM317L

____Apply 12 volts to the center pin of J6 in the center of the PCB

Measure 8 volts on PIN 1, the lower pin of J12

INTERCONNECT THE RCVR PCB TO OTHER MP+ PCBs

____This requires that ALL PCBs are completed except the XMTR PCB

This step will be detailed in a forthcoming document

TUNE UP, ALIGNMENT AND CALIBRATION

BFO alignment instructions for the RCVR using a Scope.

MP+ Freq Counter (does not need to be calibrated)

1. Solder a 5" insulated wire to the test point on the

top side of the RCVR board. The test point is the vacant

hole between D5 and D6.

2. Connect all wires between the RCVR and the FCC.

3. Run the 5" wire through the center of L6 and connect the

free end to the Freq Counter.

4. Disable the Freq Counter Offset jumper J51

5. Connect the Oscilloscope to PIN 8 of U4 on the RCVR board.

6. Power up the RCVR/FCC

7. Set to Varactor voltage (J11 center pin) to 1.00 Volts.

8. Place the MP+ into XMIT mode; place jumper on J2 on the FCC

9. Adjust C14 AND C15 for a MAXIMUM PEAK signal. This should

be near 4,913,700 Hz. This is the XMIT BFO freq.

At this point, you need to decide on your favorite audio CW note.

Most CW operators like to listen to 600 to 700 Hz signals.

Calculate the RCVE BFO freq by adding your desired audio freq

to the XMTR BFO freq. In this example, my favorite audio freq

is near 700 Hz so the calculated RCVR BFO freq = 4,914,400

10. Place the MP+ into RCVE mode; remove J2 jumper

11. Adjust C14 on the RCVR to 4,914,400 or YOUR freq.

12. Place the MP+ into XMIT mode; replace J2 jumper

13. Adjust C15 on the RCVR to 4,913,700 or YOUR freq.

14. Repeat steps 10 thru 13 until there is no more

interaction between C14 and C15 adjustments.

BFO alignment instructions for the RCVR without using a Scope.

MP+ Freq Counter (does not need to be calibrated)

The BPF must be aligned before calibrating the BFO.

1. Interconnect all six MP+ PC boards along

with all controls and the speaker.

2. Connect the Freq Counter to the test point in the vacant

hole between D5 and D6. If you have not soldered a small

wire to the test point, do so now; about 1/2" will do.

3. Disable the Freq Counter Offset jumper J51

4. Connect an antenna to the BPF on the 40 meter port

Enable the RCVR PreAmp with jumpers J2, J4 and J5.

5. Power up the MP+

6. Set the PLL to 7040 on 40 meters

7. Set to Varactor voltage (J11 center pin) to 1.00 Volts.

8. Also adjust C14, C15, C20, C24 and C42 for maximum speaker noise.

9. Listen to a signal source from the antenna; either a CW QSO or

a locally generated signal. Tune across the signal and lock it

to a comfortable audio peak frequency near 700 Hz.

You will have to adjust C14 and C15 again to accomplish this.

Make sure that when you tune across the CW note that the signal

drops out of the Xtal Filter bandpass at high audio freqs and

also that the signal is NOT audible on the other sideband.

When you find a good adjustment for C14 and C15, check the

Freq Counter. It should read near 4,914,400 Hz +/- 100 Hz

This is the RCVE BFO freq.

Calculate the XMIT BFO freq by subtracting your desired audio freq

to the RCVR BFO freq. In this example, my favorite audio freq

is near 700 Hz so the calculated XMTR BFO freq = 4,913,700

10. Place the MP+ into XMIT mode; place jumper on J2

11. Adjust C15 on the RCVR to 4,913,700 or YOUR freq.

12. Place the MP+ into RCVE mode; remove J2 jumper

13. Adjust C14 on the RCVR to 4,914,400 or YOUR freq.

14. Repeat steps 10 thru 13 until there is no more

interaction between C14 and C15 adjustments.

NEED HELP?

Email me ... w8diz at fpqrp.com