Direct Digital Synthesizer "Development Kit"

Download the expresspcb.com file

This page last updated on Tue, 13 Jul 2021 17:12:13 -0400

*** Discontinued ***

PDF file DDS Instructions in (English) [633K] submitted of Jon, EA2SN

PDF file DDS Instructions in (Spanish) [631K] submitted of Jon, EA2SN

Tutorial for adding a keypad to the DDS Kit by Bruce, W8BH

Tutorial for adding memories to the DDS Kit by Bruce, W8BH

Tutorial for adding an event button to the DDS Kit by Bruce, W8BH

Tutorial for using EEPROM in the DDS Kit by Bruce, W8BH

Tutorial for Iambic Keyer for the DDS Kit by Bruce, W8BH

Tutorial for Memory Keyer for the DDS Kit by Bruce, W8BH

Tutorial for Memory Keyer II for the DDS Kit by Bruce, W8BH

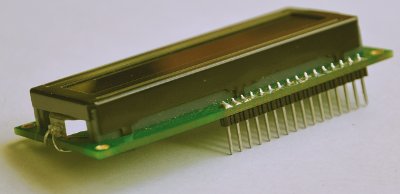

Click on the DDS Manual Link for information how the DDS works.

Building Instructions:

1. Inventory all Parts

The Kit includes two plastic parts bags; one with all the resistors; the other with the remaining parts.

The parts bags may contain extra resistors and capacitors that are not used.

2. Install all 1/4 Watt Resistors.

Note: Bend the resistor leads a sharp 90 degrees from the body

____R4: 10 Brown-Black-Black-Gold

____R11: 120 Brown-Red-Brown-Gold

____R22: 51 Green-Brown-Black-Gold

3. Install all 1/8 Watt Resistors.

Note: Bend the resistor leads a sharp 90 degrees from the body

____R1,5,7,8,9,10,23,24,25,26: 10K Brown-Black-Orange-Gold

____R2,13,14: 100 Brown-Black-Brown-Gold

____R3,19,27,28: 1K0 Brown-Black-Red-Gold

____R6,35: 620 Blue-Red-Brown-Gold

____R12: 2K7 Red-Violet-Red-Gold

____R15,16,17: 4K7 Yellow-Violet-Red-Gold

____R18: 330 Orange-Orange-Brown-Gold

____R20: 51 Green-Brown-Black-Gold

____R21: 3R3 Orange-Orange-Gold-Gold

Note: If the DDS Receive output drives a +7dBM Diode Ring Mixer then place a jumper wire at R31 else

if the DDS Receive output drives a 602 Gilbert Cell Mixer then install resistors R29,31,33 else

design your own Receive output level resistor pad.

____R29: 100 Brown-Black-Brown-Gold

____R31: 75 Violet-Green-Black-Gold

____R33: 22 Red-Red-Black-Gold

Note: If the DDS Transmit output drives a +7dBM Diode Ring Mixer then place a jumper wire at R32 else

if the DDS Transmit output drives a 602 Gilbert Cell Mixer then install resistors R30,32,34 else

design your own Transmit output level resistor pad.

____R30: 100 Brown-Black-Brown-Gold

____R32: 75 Violet-Green-Black-Gold

____R34: 22 Red-Red-Black-Gold

4. Install three 14 pin DIP sockets.

____Position the socket notches at PIN-1/14 and solder.

5. Install the 20.48 MHz Crystal about 1/32 inch above the PCB.

____Insert the Crystal in the PCB and tilt it; hold with one finger and solder. Straighten the XTAL.

6. Install the following capacitors on the digital side (right side) of the PCB.

____C1,4,5,6,7: 100n yellow axial lead bypass capacitors

____C2: 40p yellow trimmer capacitor; FLAT SIDE toward C1 (picture shows a green trimmer)

____C3: 22p NPO axial lead capacitor

7. Install type 43 ferrite binocular below C5.

There are two binoculars in the parts kit; one has rounded corners and is shiny black, the other has sharp corners and is dull black.

The shiny, rounded corners ferrite binocular is a type -43; the other is a type -61.

Cut 4 inches of 30 GA green wire and insert 4 complete turns through the -43 binocular.

One turn is defined are a wire running through BOTH HOLES of the binocular.

Strip the insulation off the wires all the way down to the body of the binocular core.

Tin the wires.

____L1: Insert the BN-43-2402 binocular filter inductor (standing up) and solder.

8. Install Red LED at .

____D1: Red LED; note polarity (flat side) and solder.

9. Install electrolytic capacitors.

____C8,9: 47uF; note polarity (+) and solder.

10. Install 4 pin reset push putton; note polaririty; only fints one way into the PCB

____RESET: Insert and solder.

11. Install the 6 pin programming header to the left of C8

____Solder.

12. Install the 3 terminal voltage regulator in lower right corner of the PCB (not labeled).

____U3: LM7805AC; note polarity; Metal TAB toward C8; solder.

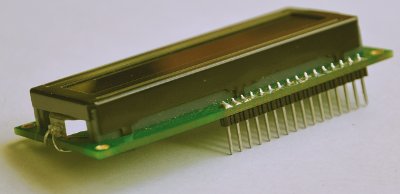

13. Install the 16-PIN female LCD header on the left side of the PCB

Before installing the female LCD header, you might want to consider how and where you want the LCD to display.

You may want to make an extension cable by soldering 16 wires between the PCB and the female header.

____Install and solder both male and female, header and socket.

14. Connect a 3-PIN header at J2 or connect power wires to J2; center pin is +12V (wires are not supplied)

____+12V + GND wires: solder.

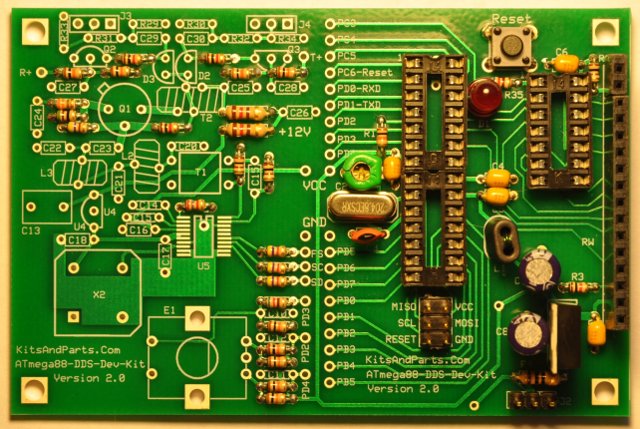

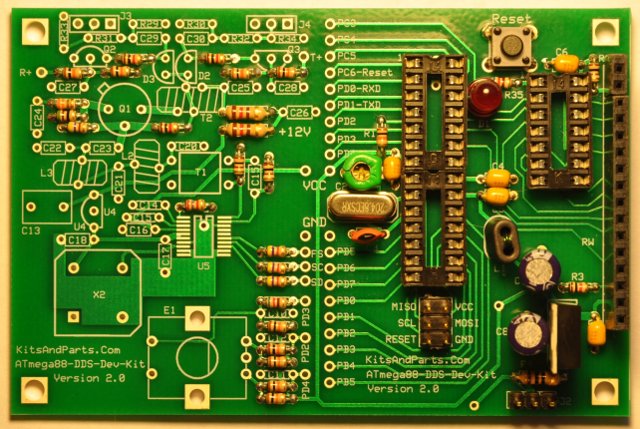

Click image to enlarge in a new window.

15. Apply 12Vdc power to J2

____Measure 5 volts across C7; if not 5V then fix the problem before proceeding.

16. Install the surface mount DDS chip (optionally installed by kitsandparts)

*** Please be carefull installing the AD9834 ***

Align the chip on the SMT pad, PIN-1 toward R12. Tack solder one corner of the DDS chip.

Solder the remaining pins to the SMT pad. Use solder wick to remove solder shorts.

Review soldering mess using high power magnifying glass, optionally check for shorts using ohm meter.

____AD9834CRUZ

17. Install type 61 ferrite binocular above R12.

There are two binoculars in the parts kit; one has rounded corners and is shiny black, the other has sharp corners and is dull black.

The shiny, rounded corners ferrite binocular is a type -43; the other is a type -61.

Cut 8 inches of 30 GA red wire and insert 6 complete turns through the -61 binocular.

The binocular holes are small so make sure the turns are tight to allow additional winding to be added.

One turn is defined as one wire running through BOTH HOLES of the binocular in a U patern.

Cut 4 inches of 30 GA green wire and insert 3 complete turns through the -61 binocular.

The completed transformer should have 2 red wires coming out one end of the binocular and 2 green wires on the other end.

Strip the insulation off the wires all the way down to the body of the binocular core.

Tin the wires.

____L1: Insert the BN-61-2402 binocular transformer (red wires toward R13), pull leads tight and solder.

18. Install the following capacitors on the DDS side (left side) of the PCB.

Note that C15 is labeled twice (in error) on the PCB. C15 in the next step is between C14 and C16.

____C15,18,23,24,25,29,30: 47n yellow axial lead capacitors

____Install a jumper (discarded resistor lead) at location labeled C15 between R13 and R14

____C14,16,17,26: 100n yellow axial lead capacitors

____C10,11,12,27,28: 10n yellow radial lead disk capacitors

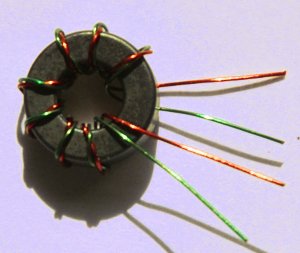

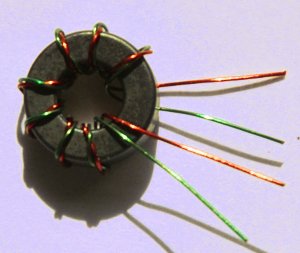

19. Install T2, a bifilar wound transformer.

Prepare 8 inches of 30 GA dual red/green magnet wire. Twist tightly to about 4 twists per inch.

Wind 8 turns, evenly and tight through the body of the FT37-43 ferrite toroid.

Trim leads to about half inch from the toroid body. Remove insulation up to the body of the ferrite.

1. GREEN WIRE connects to D2

2. RED WIRE connects to C25

3. GREEN WIRE connects to Q1

4. RED WIRE connect to R19.

____FT37-43 Strip and Tin leads; and install.

20. Install two T30-6 yellow toroid inductors (low pass filter cores).

Prepare 2 pieces of 7 inches of 26 GA red magnet wire.

Wind 8 turns of the wire through one yellow toroid. Repeat for the other toroid.

Strip the insulation off the wires all the way down to the body of the toroid cores.

Tin the wires.

____L2,3: Install the T37-6 toroids (standing up) and solder.

21. Install large yellow capacitor and 3.3 volt regulator

____C13: 330n yellow radial lead capacitor

____U4: 78L33 - 3 terminal voltage regulator; observe polarity

22. Install low pass filter capacitors

____C20,22: 100p

____C21: 220p

23. Install semiconductors

____Q1: 2N5109 - install about 1/16 inch or 2 mm above the PCB.

____Q2,3: 2N3904 - install with about 1/4 inch or 6 mm leads above the PCB. Observe polarity and do not overheat.

____D2,3: MPN3700 - install the PIN diodes all the way against the PCB. Observe polarity and do not overheat.

24. Install the 100 MHz Clock

____X2: 100 MHz - observe polarity; Squared corner points toward the lower left corner of the PCB

25. Install the Rotary Mechanical Encoder, a pulled part recycled from a Panasonic AM/FM Auto Radio.

____E1: Connect a jumper

25. Install the power connection jumpers between the DDS and CPU sections of the PCB

The following step installs jumpers but could be replaced with inductors to possibly reduce circuit noise.

____VCC: Install a jumper at VCC located in the center of the PCB and to the left of the trimmer capacitor.

____GND: Install a jumper at GND located at the lower left of the 20.48 crystal.

27. Connect the DDS section to the CPU section (a total of six (6) wire jumpers)

These connections are firmware dependent. Current firmware requires the following connections:

____PD4: Connect PD4 from the Encoder to PD4 on the ATmel CPU.

____PD2: Connect PD2 from the Encoder to PD2 on the ATmel CPU.

____PD3: Connect PD3 from the Encoder to PD3 on the ATmel CPU.

____PD5: Connect SD from the AD9834 to PD5 on the ATmel CPU.

____PD1: Connect SC from the AD9834 to PD1 on the ATmel CPU.

____PD0: Connect FS from the AD9834 to PD0 on the ATmel CPU.

28. Install the ICs; before inserting the ICs into their sockets, bend the IC pins so that they are at

sharp right angles to the IC`s plastic body. The easiest way to bend all leads uniformly is to place

the IC legs on a flat table and push/press the body of the IC against the table. DO both sides.

____U1: ATmega88PA-20 - install observing PIN-1 polarity

____U2:74HC164 - install observing PIN-1 polarity

29. Connect the LCD to the PCB.

____OK

30. Momentarily connect 12 volt power to the PCB, observing current draw (if possible)

Current consumption should be about 120 milliamps.

When the DDS powes up, the LED should flash twice and then the LCD should display 10,000,000 Hz.

If all is OK at this point, connect 12 volts to either the TRANSMIT or RECEIVE control lines

and measure/view 10 MHz output from the corresponding TRANSMIT or RECEIVE outputs at J3/4

Output level into a 50 ohm dummy load should be about 4.8 volts Peak-to-Peak at 10 MHz,

provided that there is no resistor pad in the output section on the PCB.

____OK

31. Assuming that all is OK to this point, the next step is to set up the DDS as a development platform.

Still step is optional; not required if you plan to use teh DDS Kit as a Sig_Gen or VFO.

Click on the Development Platform Link for information to update and/or modify the firmware.

Click image to enlarge in a new window.

Download the expresspcb.com file

This page last updated on Tue, 13 Jul 2021 17:12:13 -0400

*** Discontinued ***

PDF file DDS Instructions in (English) [633K] submitted of Jon, EA2SN

PDF file DDS Instructions in (Spanish) [631K] submitted of Jon, EA2SN

Tutorial for adding a keypad to the DDS Kit by Bruce, W8BH

Tutorial for adding memories to the DDS Kit by Bruce, W8BH

Tutorial for adding an event button to the DDS Kit by Bruce, W8BH

Tutorial for using EEPROM in the DDS Kit by Bruce, W8BH

Tutorial for Iambic Keyer for the DDS Kit by Bruce, W8BH

Tutorial for Memory Keyer for the DDS Kit by Bruce, W8BH

Tutorial for Memory Keyer II for the DDS Kit by Bruce, W8BH

Click on the DDS Manual Link for information how the DDS works.

Building Instructions:

1. Inventory all Parts

The Kit includes two plastic parts bags; one with all the resistors; the other with the remaining parts.

The parts bags may contain extra resistors and capacitors that are not used.

2. Install all 1/4 Watt Resistors.

Note: Bend the resistor leads a sharp 90 degrees from the body

____R4: 10 Brown-Black-Black-Gold

____R11: 120 Brown-Red-Brown-Gold

____R22: 51 Green-Brown-Black-Gold

3. Install all 1/8 Watt Resistors.

Note: Bend the resistor leads a sharp 90 degrees from the body

____R1,5,7,8,9,10,23,24,25,26: 10K Brown-Black-Orange-Gold

____R2,13,14: 100 Brown-Black-Brown-Gold

____R3,19,27,28: 1K0 Brown-Black-Red-Gold

____R6,35: 620 Blue-Red-Brown-Gold

____R12: 2K7 Red-Violet-Red-Gold

____R15,16,17: 4K7 Yellow-Violet-Red-Gold

____R18: 330 Orange-Orange-Brown-Gold

____R20: 51 Green-Brown-Black-Gold

____R21: 3R3 Orange-Orange-Gold-Gold

Note: If the DDS Receive output drives a +7dBM Diode Ring Mixer then place a jumper wire at R31 else

if the DDS Receive output drives a 602 Gilbert Cell Mixer then install resistors R29,31,33 else

design your own Receive output level resistor pad.

____R29: 100 Brown-Black-Brown-Gold

____R31: 75 Violet-Green-Black-Gold

____R33: 22 Red-Red-Black-Gold

Note: If the DDS Transmit output drives a +7dBM Diode Ring Mixer then place a jumper wire at R32 else

if the DDS Transmit output drives a 602 Gilbert Cell Mixer then install resistors R30,32,34 else

design your own Transmit output level resistor pad.

____R30: 100 Brown-Black-Brown-Gold

____R32: 75 Violet-Green-Black-Gold

____R34: 22 Red-Red-Black-Gold

4. Install three 14 pin DIP sockets.

____Position the socket notches at PIN-1/14 and solder.

5. Install the 20.48 MHz Crystal about 1/32 inch above the PCB.

____Insert the Crystal in the PCB and tilt it; hold with one finger and solder. Straighten the XTAL.

6. Install the following capacitors on the digital side (right side) of the PCB.

____C1,4,5,6,7: 100n yellow axial lead bypass capacitors

____C2: 40p yellow trimmer capacitor; FLAT SIDE toward C1 (picture shows a green trimmer)

____C3: 22p NPO axial lead capacitor

7. Install type 43 ferrite binocular below C5.

There are two binoculars in the parts kit; one has rounded corners and is shiny black, the other has sharp corners and is dull black.

The shiny, rounded corners ferrite binocular is a type -43; the other is a type -61.

Cut 4 inches of 30 GA green wire and insert 4 complete turns through the -43 binocular.

One turn is defined are a wire running through BOTH HOLES of the binocular.

Strip the insulation off the wires all the way down to the body of the binocular core.

Tin the wires.

____L1: Insert the BN-43-2402 binocular filter inductor (standing up) and solder.

8. Install Red LED at .

____D1: Red LED; note polarity (flat side) and solder.

9. Install electrolytic capacitors.

____C8,9: 47uF; note polarity (+) and solder.

10. Install 4 pin reset push putton; note polaririty; only fints one way into the PCB

____RESET: Insert and solder.

11. Install the 6 pin programming header to the left of C8

____Solder.

12. Install the 3 terminal voltage regulator in lower right corner of the PCB (not labeled).

____U3: LM7805AC; note polarity; Metal TAB toward C8; solder.

13. Install the 16-PIN female LCD header on the left side of the PCB

Before installing the female LCD header, you might want to consider how and where you want the LCD to display.

You may want to make an extension cable by soldering 16 wires between the PCB and the female header.

____Install and solder both male and female, header and socket.

14. Connect a 3-PIN header at J2 or connect power wires to J2; center pin is +12V (wires are not supplied)

____+12V + GND wires: solder.

Click image to enlarge in a new window.

15. Apply 12Vdc power to J2

____Measure 5 volts across C7; if not 5V then fix the problem before proceeding.

16. Install the surface mount DDS chip (optionally installed by kitsandparts)

*** Please be carefull installing the AD9834 ***

Align the chip on the SMT pad, PIN-1 toward R12. Tack solder one corner of the DDS chip.

Solder the remaining pins to the SMT pad. Use solder wick to remove solder shorts.

Review soldering mess using high power magnifying glass, optionally check for shorts using ohm meter.

____AD9834CRUZ

17. Install type 61 ferrite binocular above R12.

There are two binoculars in the parts kit; one has rounded corners and is shiny black, the other has sharp corners and is dull black.

The shiny, rounded corners ferrite binocular is a type -43; the other is a type -61.

Cut 8 inches of 30 GA red wire and insert 6 complete turns through the -61 binocular.

The binocular holes are small so make sure the turns are tight to allow additional winding to be added.

One turn is defined as one wire running through BOTH HOLES of the binocular in a U patern.

Cut 4 inches of 30 GA green wire and insert 3 complete turns through the -61 binocular.

The completed transformer should have 2 red wires coming out one end of the binocular and 2 green wires on the other end.

Strip the insulation off the wires all the way down to the body of the binocular core.

Tin the wires.

____L1: Insert the BN-61-2402 binocular transformer (red wires toward R13), pull leads tight and solder.

18. Install the following capacitors on the DDS side (left side) of the PCB.

Note that C15 is labeled twice (in error) on the PCB. C15 in the next step is between C14 and C16.

____C15,18,23,24,25,29,30: 47n yellow axial lead capacitors

____Install a jumper (discarded resistor lead) at location labeled C15 between R13 and R14

____C14,16,17,26: 100n yellow axial lead capacitors

____C10,11,12,27,28: 10n yellow radial lead disk capacitors

19. Install T2, a bifilar wound transformer.

Prepare 8 inches of 30 GA dual red/green magnet wire. Twist tightly to about 4 twists per inch.

Wind 8 turns, evenly and tight through the body of the FT37-43 ferrite toroid.

Trim leads to about half inch from the toroid body. Remove insulation up to the body of the ferrite.

1. GREEN WIRE connects to D2

2. RED WIRE connects to C25

3. GREEN WIRE connects to Q1

4. RED WIRE connect to R19.

____FT37-43 Strip and Tin leads; and install.

20. Install two T30-6 yellow toroid inductors (low pass filter cores).

Prepare 2 pieces of 7 inches of 26 GA red magnet wire.

Wind 8 turns of the wire through one yellow toroid. Repeat for the other toroid.

Strip the insulation off the wires all the way down to the body of the toroid cores.

Tin the wires.

____L2,3: Install the T37-6 toroids (standing up) and solder.

21. Install large yellow capacitor and 3.3 volt regulator

____C13: 330n yellow radial lead capacitor

____U4: 78L33 - 3 terminal voltage regulator; observe polarity

22. Install low pass filter capacitors

____C20,22: 100p

____C21: 220p

23. Install semiconductors

____Q1: 2N5109 - install about 1/16 inch or 2 mm above the PCB.

____Q2,3: 2N3904 - install with about 1/4 inch or 6 mm leads above the PCB. Observe polarity and do not overheat.

____D2,3: MPN3700 - install the PIN diodes all the way against the PCB. Observe polarity and do not overheat.

24. Install the 100 MHz Clock

____X2: 100 MHz - observe polarity; Squared corner points toward the lower left corner of the PCB

25. Install the Rotary Mechanical Encoder, a pulled part recycled from a Panasonic AM/FM Auto Radio.

____E1: Connect a jumper

25. Install the power connection jumpers between the DDS and CPU sections of the PCB

The following step installs jumpers but could be replaced with inductors to possibly reduce circuit noise.

____VCC: Install a jumper at VCC located in the center of the PCB and to the left of the trimmer capacitor.

____GND: Install a jumper at GND located at the lower left of the 20.48 crystal.

27. Connect the DDS section to the CPU section (a total of six (6) wire jumpers)

These connections are firmware dependent. Current firmware requires the following connections:

____PD4: Connect PD4 from the Encoder to PD4 on the ATmel CPU.

____PD2: Connect PD2 from the Encoder to PD2 on the ATmel CPU.

____PD3: Connect PD3 from the Encoder to PD3 on the ATmel CPU.

____PD5: Connect SD from the AD9834 to PD5 on the ATmel CPU.

____PD1: Connect SC from the AD9834 to PD1 on the ATmel CPU.

____PD0: Connect FS from the AD9834 to PD0 on the ATmel CPU.

28. Install the ICs; before inserting the ICs into their sockets, bend the IC pins so that they are at

sharp right angles to the IC`s plastic body. The easiest way to bend all leads uniformly is to place

the IC legs on a flat table and push/press the body of the IC against the table. DO both sides.

____U1: ATmega88PA-20 - install observing PIN-1 polarity

____U2:74HC164 - install observing PIN-1 polarity

29. Connect the LCD to the PCB.

____OK

30. Momentarily connect 12 volt power to the PCB, observing current draw (if possible)

Current consumption should be about 120 milliamps.

When the DDS powes up, the LED should flash twice and then the LCD should display 10,000,000 Hz.

If all is OK at this point, connect 12 volts to either the TRANSMIT or RECEIVE control lines

and measure/view 10 MHz output from the corresponding TRANSMIT or RECEIVE outputs at J3/4

Output level into a 50 ohm dummy load should be about 4.8 volts Peak-to-Peak at 10 MHz,

provided that there is no resistor pad in the output section on the PCB.

____OK

31. Assuming that all is OK to this point, the next step is to set up the DDS as a development platform.

Still step is optional; not required if you plan to use teh DDS Kit as a Sig_Gen or VFO.

Click on the Development Platform Link for information to update and/or modify the firmware.

Click image to enlarge in a new window.